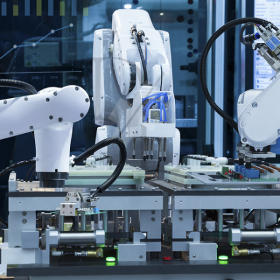

Metalworking has entered a new era of innovation, with high end automation solutions leading the charge. These advanced systems combine precision, efficiency, and adaptability, empowering manufacturers to achieve unparalleled productivity while maintaining superior quality.

Why High End Automation Solutions for Metalworking Matter

Precision That Drives Excellence

High end automation solutions for metalworking deliver unmatched precision, ensuring every cut, bend, and finish meets the highest standards. These systems are essential for industries where accuracy is non-negotiable, from aerospace to automotive manufacturing.

Benefits of Enhanced Precision

- Reduces errors and material waste

- Ensures consistent product quality

- Boosts customer satisfaction with flawless results

Efficiency That Saves Time and Resources

Automation optimizes workflows by reducing downtime and accelerating production processes. Manufacturers using these solutions experience faster project completion times and lower operational costs.

Key Efficiency Advantages

- Minimizes manual intervention for faster output

- Streamlines repetitive tasks for better resource allocation

- Reduces labor costs without sacrificing productivity

Features That Define High End Automation Solutions

Adaptive Technology for Versatile Applications

Modern automation solutions are designed to adapt to a variety of metalworking tasks, from cutting and welding to forming and finishing. This versatility makes them invaluable for manufacturers with diverse production needs.

How Adaptability Benefits Metalworking

- Handles complex geometries with ease

- Supports a wide range of materials and thicknesses

- Ensures seamless integration with existing equipment

Real-Time Monitoring for Better Control

Integrated sensors and software provide real-time monitoring, allowing operators to track performance and identify potential issues before they escalate. This enhances operational reliability and efficiency.

Advantages of Real-Time Insights

- Improves decision-making with accurate data

- Reduces downtime through proactive maintenance

- Enhances overall system performance and safety

Intelligent Software Integration

High end automation solutions for metalworking include intuitive software that simplifies programming and operation. Features like AI-powered optimization and machine learning improve overall productivity.

Why Smart Software Matters

- Automates complex processes for greater efficiency

- Enhances flexibility with customizable workflows

- Simplifies operator training and reduces human error

Applications of High End Automation in Metalworking

Laser Cutting for Unparalleled Accuracy

Laser cutting is a cornerstone of modern metalworking. Automation enhances this process by ensuring precise cuts, faster speeds, and the ability to handle intricate designs.

Benefits of Automated Laser Cutting

- Achieves sharp, clean edges with minimal waste

- Handles high-volume production efficiently

- Reduces heat-affected zones for better material integrity

Robotic Welding for Consistent Strength

Automation revolutionizes welding by delivering consistent and high-quality welds, even for complex projects. Robotic systems ensure accuracy, speed, and repeatability.

Advantages of Robotic Welding

- Improves weld quality and structural integrity

- Speeds up production without compromising precision

- Handles challenging angles and positions effortlessly

CNC Machining for Complex Parts

Computer numerical control (CNC) machining is essential for producing detailed and complex components. Automation enhances this process by increasing speed, accuracy, and repeatability.

Key Features of Automated CNC Machining

- Handles intricate designs with exceptional precision

- Reduces tool wear through optimized programming

- Ensures consistent quality across large production runs

How Automation Solutions Enhance Productivity

Minimizing Downtime with Predictive Maintenance

Predictive maintenance uses real-time data to anticipate potential equipment failures. This approach ensures machines remain operational, reducing downtime and maintenance costs.

Why Predictive Maintenance Is Essential

- Prevents unplanned interruptions in production

- Extends the lifespan of critical equipment

- Optimizes maintenance schedules for cost savings

Streamlining Workflows for Faster Output

Automation solutions eliminate bottlenecks by streamlining workflows and automating repetitive tasks. This improves overall production efficiency and throughput.

Benefits of Optimized Workflows

- Shortens lead times for customer orders

- Increases flexibility to handle urgent projects

- Enhances coordination across departments

Safety and Sustainability in Automated Metalworking

Enhancing Workplace Safety

High end automation solutions for metalworking prioritize safety with features like automatic shutoffs, remote monitoring, and integrated safety protocols. These systems reduce the risk of workplace accidents.

Safety Features That Matter

- Eliminates exposure to hazardous tasks

- Monitors equipment for potential safety hazards

- Complies with industry safety standards

Supporting Sustainable Manufacturing

Automation reduces material waste, improves energy efficiency, and supports sustainable practices. This aligns with the growing demand for eco-friendly manufacturing.

How Automation Promotes Sustainability

- Optimizes resource usage to minimize waste

- Reduces emissions through efficient processes

- Encourages the use of recyclable materials

Choosing the Right Automation Solutions for Your Needs

Assessing Production Goals and Challenges

Before investing in automation, manufacturers should identify their specific production goals and challenges. This ensures the chosen solution aligns with their needs and delivers maximum ROI.

Key Considerations

- What processes require improvement or automation?

- How can automation address current inefficiencies?

- What level of scalability is needed for future growth?

Evaluating Compatibility and Support

High end automation solutions for metalworking should integrate seamlessly with existing systems and include reliable support. Manufacturers should prioritize solutions with proven performance and strong after-sales service.

Features to Look For

- Compatibility with current equipment and software

- Availability of training and technical support

- Positive reviews and case studies from similar industries

The Future of High End Automation in Metalworking

AI and Machine Learning Advancements

Artificial intelligence and machine learning are transforming automation, enabling smarter decision-making and greater adaptability. These technologies will further enhance efficiency and precision.

Predicted Innovations

- Self-optimizing machines that adjust to real-time data

- AI-driven quality control for defect detection

- Adaptive systems that learn from production trends

Expanding Accessibility for Small Manufacturers

As automation technology becomes more affordable, smaller manufacturers can benefit from high end solutions. This democratization of technology will drive innovation and competitiveness.

Impact on the Industry

- Levels the playing field for businesses of all sizes

- Encourages widespread adoption of advanced systems

- Promotes innovation through accessible technology

Testimonials from Industry Leaders

Stories of Success with Automation

Manufacturers who have implemented high end automation solutions for metalworking report significant improvements in productivity, quality, and customer satisfaction.

Common Praise

- “Our output has doubled without increasing labor costs.”

- “The precision we’ve achieved is unmatched.”

- “Automation has transformed our workflow efficiency.”

Tips from Experienced Users

- Invest in scalable solutions to accommodate future growth.

- Train staff thoroughly to maximize system potential.

- Monitor data regularly for continuous optimization.

Conclusion

High end automation solutions for metalworking are redefining the industry by enhancing precision, efficiency, and safety. These systems empower manufacturers to meet growing demands while maintaining superior quality and sustainability.

Investing in automation ensures your business remains competitive and ready for the future. Explore the latest technologies today to revolutionize your metalworking operations and achieve unparalleled success.