Modern machining demands precision, speed, and flexibility. Premium CAD CAM software for machining delivers advanced tools to streamline every aspect of the design-to-production process. Whether you’re crafting intricate components or managing large-scale projects, this software enhances productivity and ensures flawless results.

Why Choose Premium CAD CAM Software for Machining?

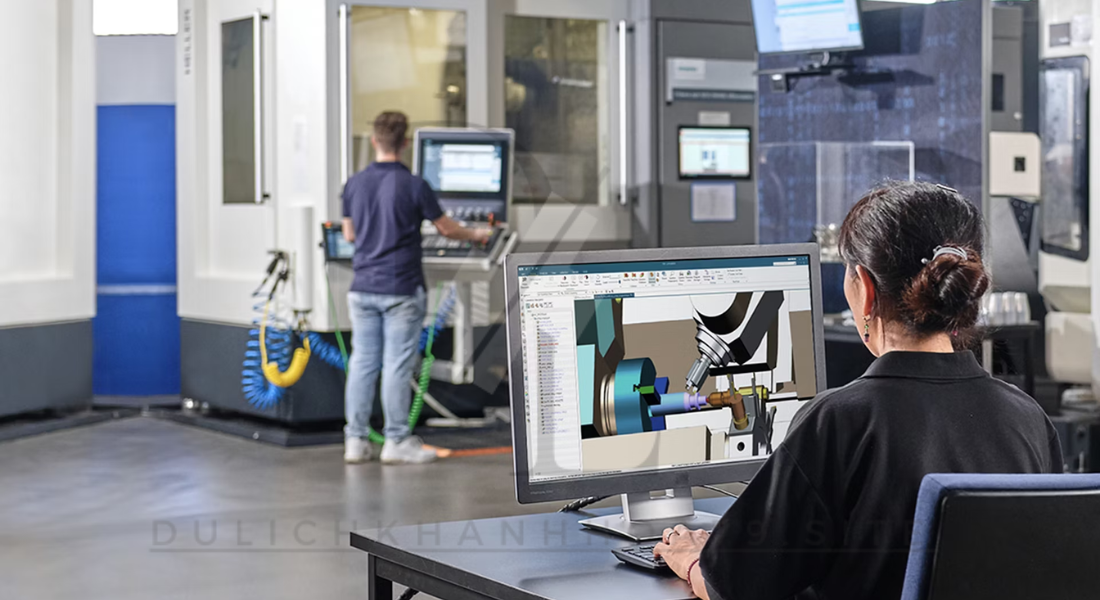

In today’s competitive market, efficiency is vital. Premium CAD CAM software for machining offers powerful features that simplify complex tasks and boost accuracy. It integrates seamlessly with CNC machines, enabling users to move from design to manufacturing with ease.

This technology supports designers, engineers, and machinists by providing intuitive tools for creating, simulating, and optimizing workflows. It’s more than software—it’s a game-changing solution for modern manufacturing.

Precision Design Made Simple

Creating precise designs is the foundation of successful machining. With intuitive tools, premium CAD CAM software for machining allows users to design intricate components effortlessly.

Whether you’re working on 2D layouts or 3D models, the software ensures accuracy at every step. Advanced features like parametric modeling and associative design updates simplify revisions, saving time and ensuring consistency.

Streamline Manufacturing with Seamless Integration

Efficiency hinges on smooth transitions between design and production. Premium CAD CAM software for machining bridges this gap by generating accurate toolpaths and machine-ready code.

This integration eliminates errors and reduces manual adjustments, ensuring that designs translate perfectly into physical parts. Users gain the confidence of knowing their production processes align seamlessly with their designs.

Enhance Productivity with Automation

Repetitive tasks slow down workflows and increase the risk of errors. Automation tools in premium CAD CAM software for machining solve this problem by streamlining processes like toolpath generation, nesting, and simulations.

By automating routine operations, the software frees up time for more critical tasks, allowing machinists to focus on innovation and problem-solving. This efficiency boosts output while maintaining quality.

Simulations for Error-Free Production

Mistakes during production can lead to costly delays and wasted materials. Premium CAD CAM software for machining provides robust simulation tools that allow users to test their designs before manufacturing begins.

These simulations identify potential collisions, tool errors, and inefficiencies, giving users the opportunity to make adjustments early. This proactive approach minimizes downtime and maximizes efficiency.

Advanced Toolpath Strategies for Complex Projects

Machining intricate parts requires precision and strategy. Premium CAD CAM software for machining includes advanced toolpath options like 5-axis machining, adaptive clearing, and high-speed roughing.

These features ensure efficient material removal while preserving surface quality. Complex geometries become manageable, enabling users to meet the most demanding project requirements.

Optimize Costs with Intelligent Resource Management

Manufacturers face constant pressure to reduce costs without sacrificing quality. Premium CAD CAM software for machining optimizes resource usage by calculating efficient toolpaths and minimizing material waste.

By maximizing machine uptime and reducing cycle times, the software helps users achieve cost-effective production. This optimization supports profitability while maintaining top-tier results.

Adapt to Any Industry or Application

Flexibility is essential in modern machining. Premium CAD CAM software for machining supports a wide range of industries, including aerospace, automotive, medical, and consumer goods.

Whether you’re crafting prototypes, mass-producing components, or creating custom designs, this software adapts to your needs. Its versatility ensures you can tackle any project with confidence.

Enhance Collaboration Across Teams

Manufacturing often involves multiple teams working together. Premium CAD CAM software for machining fosters collaboration by providing tools for sharing designs, simulations, and production data.

This connectivity ensures everyone stays aligned, reducing miscommunication and improving project outcomes. Teams can work cohesively, from design through to final production.

Simplify Workflow Management

Managing complex projects requires clear oversight. Premium CAD CAM software for machining streamlines workflow management by integrating planning, scheduling, and reporting tools.

Users can monitor progress, identify bottlenecks, and ensure deadlines are met. This streamlined approach keeps projects on track and enhances overall productivity.

Cloud Connectivity for Enhanced Collaboration

In today’s interconnected world, having access to your projects from anywhere is a vital advantage. Cloud-enabled machining software offers unmatched flexibility, ensuring that users can collaborate seamlessly across different locations.

Whether a designer updates a model, a machinist fine-tunes toolpaths, or a manager oversees project progress, real-time data access keeps everyone aligned. This feature enhances team communication, streamlines workflows, and boosts overall efficiency.

Robust Security to Protect Your Work

Securing designs and sensitive production data is more important than ever. Advanced machining software integrates strong encryption protocols, controlled access, and secure storage systems to ensure peace of mind.

These safeguards keep intellectual property safe from unauthorized access or potential breaches. With these protections in place, teams can focus fully on innovation without unnecessary concerns about security risks.

Streamlined Usability for Maximum Impact

The right tools should simplify processes, not complicate them. Modern machining solutions prioritize user experience with intuitive interfaces, customizable dashboards, and step-by-step guides.

Even complex workflows become manageable with these features. Beginners quickly adapt, while seasoned professionals appreciate the efficiency gains from reduced learning curves and smoother operation.

Adaptability for Tomorrow’s Challenges

The world of manufacturing evolves rapidly, and staying competitive requires tools that grow with your needs. Innovative machining software ensures compatibility with emerging technologies and provides regular updates to meet industry demands.

This adaptability future-proofs your processes, enabling your business to handle new challenges and opportunities confidently. Investing in such tools means you’re always prepared for what’s next in the industry.

Why Experts Recommend This Solution

Professionals highlight the precision, speed, and versatility offered by advanced machining tools. They appreciate the seamless connection between design and production stages, which reduces errors and saves time.

Additionally, the ability to manage costs effectively and streamline workflows makes this software an indispensable asset. From small workshops to large-scale manufacturing facilities, users across the board recognize its value in modern production environments.

Take Your Production to the Next Level

Adopting advanced machining solutions reshapes how you design, produce, and deliver. These tools bring unparalleled accuracy, streamlined workflows, and efficiency to every stage of the process.

Whether you’re a craftsman working on custom projects or overseeing a high-volume production line, this technology equips you for success. Embrace smarter production methods today and experience the transformative benefits firsthand.

Elevate your operations and ensure your business thrives in a competitive market with cutting-edge machining tools that redefine what’s possible.