The industrial landscape is evolving rapidly, driven by advancements in robotics automation for industrial use. These systems streamline processes, improve efficiency, and reduce costs, making them essential for businesses aiming to stay competitive. This article explores how robotics automation revolutionizes industries, the benefits it delivers, and its potential to redefine manufacturing and production.

How Robotics Automation Enhances Industrial Operations

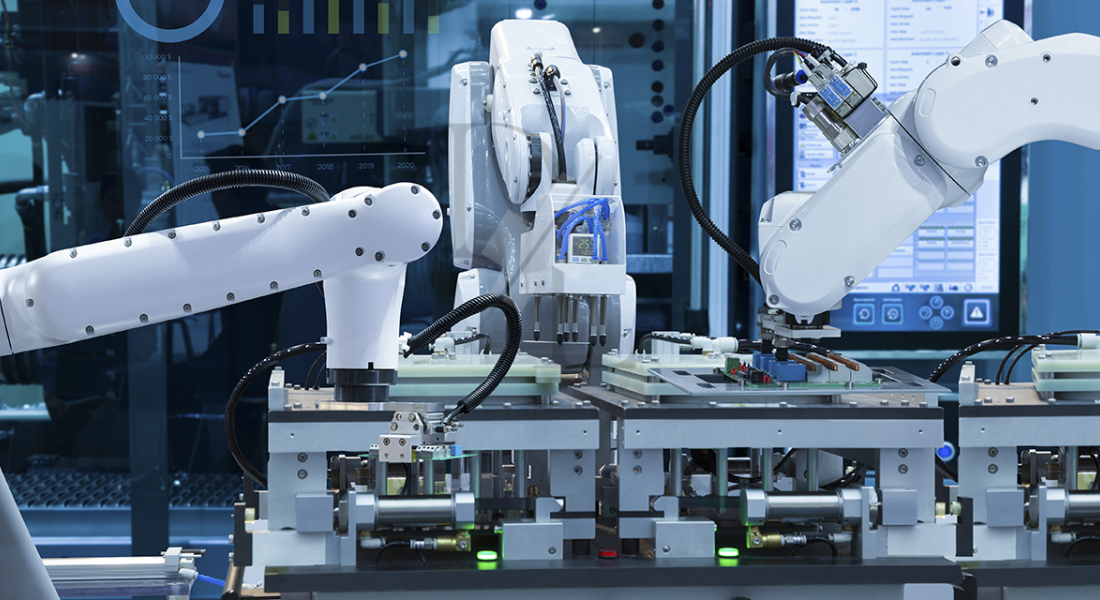

Robotics automation for industrial use integrates cutting-edge technology with traditional processes to enhance productivity and precision. Robots equipped with advanced sensors and artificial intelligence perform repetitive tasks with unmatched accuracy, reducing errors and increasing output.

From assembly lines to quality control, these automated systems ensure consistency and efficiency. They adapt to changing requirements, making them suitable for diverse industries such as automotive, electronics, and pharmaceuticals.

Increasing Efficiency Across Manufacturing Processes

Robotics automation transforms manufacturing by optimizing workflows. Automated machines handle repetitive tasks like welding, painting, and packaging with speed and accuracy. By minimizing manual intervention, these systems reduce production time while maintaining high-quality standards.

Manufacturers use robotics to monitor processes in real time, identifying inefficiencies and addressing them immediately. This proactive approach enhances overall productivity and reduces downtime, ensuring seamless operations even in high-demand environments.

Enhancing Workplace Safety with Robotics

Safety is a top priority in industrial settings, and robotics automation plays a crucial role in protecting workers. Robots take over hazardous tasks such as heavy lifting, working with toxic materials, or operating in extreme temperatures. This shift reduces workplace injuries and creates a safer environment for employees.

Collaborative robots, or cobots, work alongside humans, enhancing safety without compromising efficiency. These robots are programmed to detect and avoid collisions, ensuring smooth interaction with workers on the factory floor.

Cost Savings Through Robotics Integration

Investing in robotics automation for industrial use delivers long-term cost savings. While the initial investment may seem significant, automated systems reduce labor costs, minimize errors, and extend equipment lifespan through precise operation.

Robots also enable businesses to scale production without significantly increasing operational expenses. This scalability allows companies to meet growing demand efficiently, boosting profitability and market competitiveness.

Driving Innovation with Artificial Intelligence

Artificial intelligence enhances robotics automation, enabling machines to learn and adapt to complex tasks. AI-powered robots analyze data, predict outcomes, and make adjustments to improve performance. These capabilities make them invaluable for industries requiring high precision, such as electronics and aerospace.

AI-driven systems also optimize supply chains by forecasting demand and managing inventory. This integration ensures that resources are used efficiently, reducing waste and improving sustainability.

Customizable Solutions for Diverse Industries

Robotics automation for industrial use offers customizable solutions tailored to specific needs. From small-scale operations to large manufacturing plants, robots adapt to various tasks and environments. Businesses can choose from a wide range of systems, including robotic arms, automated guided vehicles (AGVs), and robotic process automation (RPA) software.

These versatile solutions cater to industries such as food processing, logistics, and construction, providing flexibility and efficiency regardless of the application.

Streamlining Logistics with Automated Systems

Robotics automation streamlines logistics by automating tasks such as sorting, packing, and transporting goods. AGVs navigate warehouses autonomously, reducing the need for manual labor and increasing efficiency. These vehicles ensure timely delivery of materials, improving supply chain management.

Automated systems also enhance accuracy in inventory management. Robots equipped with barcode scanners and RFID technology track stock levels in real time, eliminating errors and ensuring seamless operations.

Sustainable Practices with Robotics Automation

Robotics automation supports sustainable practices by reducing waste and energy consumption. Automated systems operate with precision, minimizing material waste during production. They also optimize energy use, lowering the carbon footprint of industrial processes.

Robots contribute to recycling initiatives by sorting and processing materials efficiently. This capability aligns with global efforts to promote sustainability, making robotics a valuable tool for environmentally conscious industries.

Improving Product Quality with Precision Robotics

Robots designed for industrial use excel in maintaining consistent product quality. These machines perform intricate tasks with precision, reducing defects and ensuring uniformity. For industries like electronics and medical devices, where accuracy is critical, robotics automation delivers unparalleled results.

Automated quality control systems detect flaws during production, allowing manufacturers to address issues immediately. This proactive approach enhances product reliability and strengthens brand reputation.

Increasing Flexibility in Production Lines

Robotics automation introduces flexibility to production lines, enabling manufacturers to adapt quickly to changing demands. Robots programmed for multiple tasks can switch between operations effortlessly, reducing setup time and costs.

This adaptability allows businesses to diversify their product offerings without significant investments in new equipment. Flexible production lines ensure companies remain competitive in dynamic markets.

Training the Workforce for Robotics Integration

As robotics automation becomes more prevalent, training employees to work with these systems is essential. Businesses invest in upskilling their workforce, ensuring they can operate, maintain, and program robots effectively.

Collaborative robots simplify this transition by allowing workers to interact with machines in familiar ways. This collaboration fosters a seamless integration of robotics into industrial operations, enhancing both productivity and employee satisfaction.

Realizing ROI with Robotics Automation

The return on investment (ROI) for robotics automation is substantial. Businesses experience increased efficiency, reduced operational costs, and improved product quality, leading to higher profitability. The ability to scale production without significant expenses further enhances ROI, making robotics a smart choice for long-term growth.

Companies that embrace automation also gain a competitive edge by delivering products faster and with greater precision. This advantage positions them as leaders in their respective industries.

The Future of Robotics Automation in Industry

The future of robotics automation for industrial use promises even greater advancements. Innovations such as 5G connectivity, edge computing, and machine learning will enhance robot capabilities, making them faster, smarter, and more versatile.

The rise of autonomous robots capable of independent decision-making will redefine how industries operate. These advancements will expand the scope of robotics, allowing them to tackle more complex tasks and enter new markets.

Choosing the Right Robotics Automation Solution

Selecting the ideal robotics automation system requires careful evaluation of business needs and goals. Consider factors such as task complexity, scalability, and budget when choosing a solution. Consulting with industry experts ensures that the selected system aligns with your operational requirements.

Partnering with reputable robotics providers guarantees access to high-quality systems and ongoing support. This collaboration ensures a successful integration of automation into your industrial processes.

Conclusion

Robotics automation for industrial use is transforming the way industries operate, delivering efficiency, safety, and sustainability. From streamlining manufacturing to enhancing logistics, these systems offer unparalleled benefits that drive growth and innovation.

Investing in robotics automation positions businesses for success in an increasingly competitive market. By embracing this technology, companies unlock new opportunities, improve operations, and secure a brighter future for their industries.